Plastic Injection Molding for Medical Devices

Manufacturing Success

Our responsiveness and flexibility tend to drive customers to us, and our execution proves that we are the best choice.

Plastic Molding Services

We specialize in injection molding. We offer a full range of plastic molding capabilities to efficiently mass-produce parts.

Learn MoreCustom Medical Injection Molding

A Full-Service ISO 13485:2016 Custom Plastic Injection Molding Company

Whether you are searching for standard or cleanroom medical injection molding services, Springboard provides the state-of-the-art medical molding services you need to stay ahead of the game. Our in-house injection molding tooling and design capabilities and massive 300,000 square feet of production space, spread across four manufacturing facilities allow us to cater to your project’s exact specifications.

To learn more about Springboard, or for more information regarding our advanced medical injection molding processes, give us a call at 916-853-0717, or check out our medical injection molding and quality assurance processes today.

Request a QuoteComplete End-to-End Medical Molding Service Capabilities

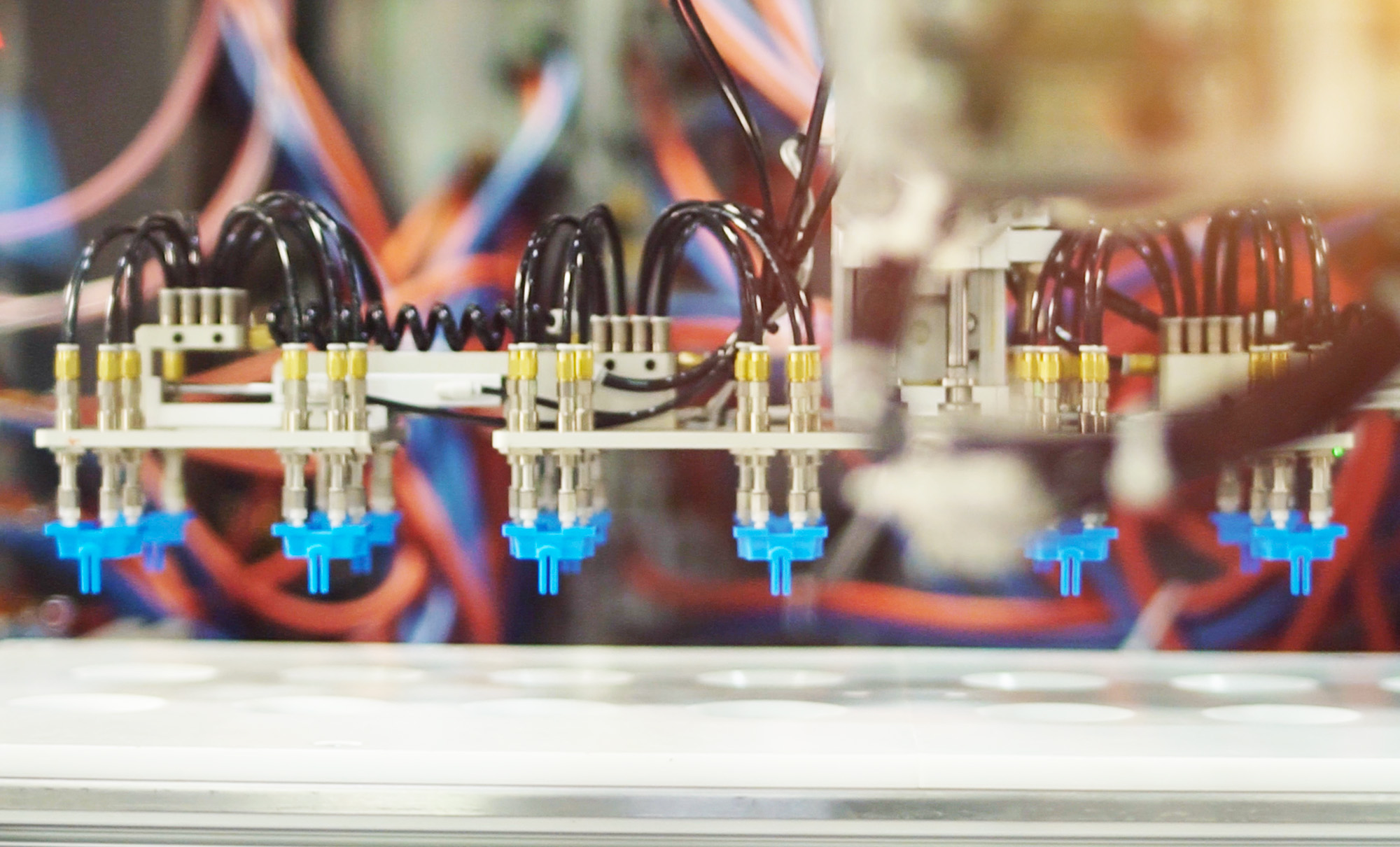

At Springboard, we provide complete end-to-end medical injection molding services for projects that require design, engineering, molding, assembly, packaging and radiation process to meet all medical standards of production. We do not outsource any of our production, molding, or tooling services.

All in-house medical molding tooling systems are designed, assembled, and packaged in the U.S. This process allows us to provide the most efficient plastic injection molding manufacturing and assembly processes in the industry. We provide the following medical injection molding services:

- Molding

- Manufacturing Assembly

- Packaging

Your Trusted Partner for

Plastic Injection Molded Products

Springboard produces high volume, quality-consistent custom plastic injection molded products. We are aware of today’s time compressed market requirements and ever changing supply demands. We remain adaptable, meeting the needs of our customers.

Medical Plastic Injection Molding

Springboard boasts a total of 4 manufacturing facilities, totaling more than 300,000 square feet of purpose-built space, enabling us to maintain Consistency, Quality and Value in all our molded products. The medical plastic injection molding process is cost-efficient, and ideal for high volume production runs and applications requiring consistency and tight tolerances. Medical molding is used for FDA approval and laboratory testing.

Cleanroom Medical Injection Molding

To meet industry demands, we have dedicated 1356 square feet of enclosed floor space to Clean Room Medical Molding. Our medical device clean room production provides ISO level 8 or better cleanroom standards for parts and components that require enhanced levels of protection for part assembly, molding, and packaging. Clean room plastic injection molding areas provide an effective way to manufacture your medical device parts and components in a clean and controlled environment.

Custom Medical Device Manufacturing Capabilities

At Springboard, we offer state-of-the-art medical injection molding and assembly services for numerous types of medical device applications in a wide range of sizes. Our medical insert molding processes can create housings for medical devices including:

- Medical Enclosures

- Medical Knobs

- Needles

- Surgical instruments and blades

- Tubes

- Dental instruments

- Medical equipment components

- Prosthetics

Medical Injection Molding Material Options

Springboard’s medical injection molding design capabilities are based on Lean Manufacturing principles. We utilize the DELMIAWorks Manufacturing ERP (formerly IQMS) System throughout our processes to manage our customer base, orders, and scheduling including process monitoring, materials inventory, warehousing, and shipping. We provide the following medical grade plastic material options for your medical molding production needs:

Additional Plastic Molding Services

Plastic injection molding and other custom plastic molding services are designed to effectively mass-produce plastic parts and/or products in a short amount of time. Plastic molding services allows thousands or even millions of high quality, high precision parts to be manufactured with perfect repeatability and with relatively quick turnaround times. At Springboard, we offer the following plastic molding services:

Overmolding

Overmolding is a standard plastic injection process that combines a base layer mold with additional plastic layers that are molded around the part. Overmolding improves product grip and ergonomics, allow for electrical insulation, or create a waterproof seal.

Insert Molding

Insert molding allows for a previously fabricated component to be fully encapsulated in a molten resin to create a finished part. Plastic insert molding is ideal for improving the strength and reliability of a component and can help save on cost and production time.

Ultrasonic Bonding

The ultrasonic bonding process utilizes high frequency sound waves to fuse together two separate workpieces. Sonic welding decreases production costs while producing high quality bonds with tight seals.

Micro Molding

Micro injection molding is highly useful in the medical and electronic industries and produces high precision parts that are extremely small, weighing in at less than one gram. Springboard has the capabilities to produce minuscule parts with intricate details and features that would be impossible to manufacture by other means.